This was one of my favourite projects during my time at university. We were tasked with creating a purely mechanical system to launch a ping pong ball into a hoop, which would then compete against classmates in a tournament. Despite sounding simple, several constraints were added: the system had to include as many mechanical components as possible from a provided list (fasteners, brakes, clutches, belts, chains, wire, springs, link mechanisms, bearings, shafts, and gears) and had to fit within a 500x700x750mm cube.

The competition was judged in four categories: weight, number of components, aesthetics, and points scored.

This challenge spurred creative thinking. Our final solution was extremely light at 167 grams, included six components (circlips, pawl brake, shaft, springs, bolts, nuts), and was aesthetically pleasing. In the final competition, we finished in a close but unfortunate second place.

This was a CAD project in second year that was my first CAD challenge beyond simple extrusions. The task was to select a household object and create an accurate model of it. For this I chose a Wii remote, attracted by its complex curves and intricate design. The final model closely matched the original controller and included motion limits in the assembly, allowing the buttons to function.

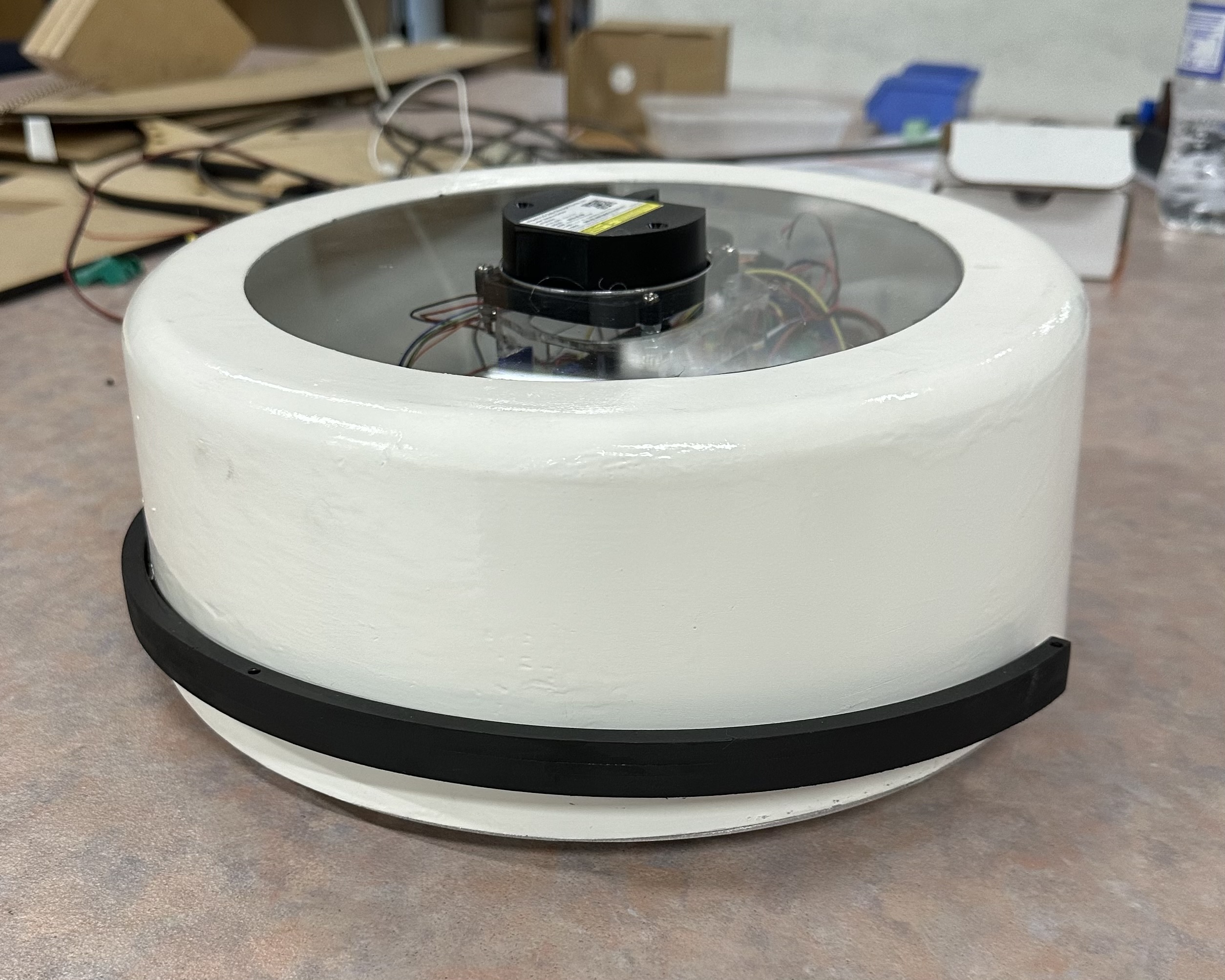

In this group project, we coordinated the design, prototyping, and business case for a new robotic vacuum cleaner. Our focus was on the autonomous object avoidance and pathing aspects of the robot excluding the design and prototyping of the suction from our scope. To achieve autonomous navigation, we utilised a 2D scanning Lidar, infrared cliff sensors, and limit switches to ensure safe and efficient operation.

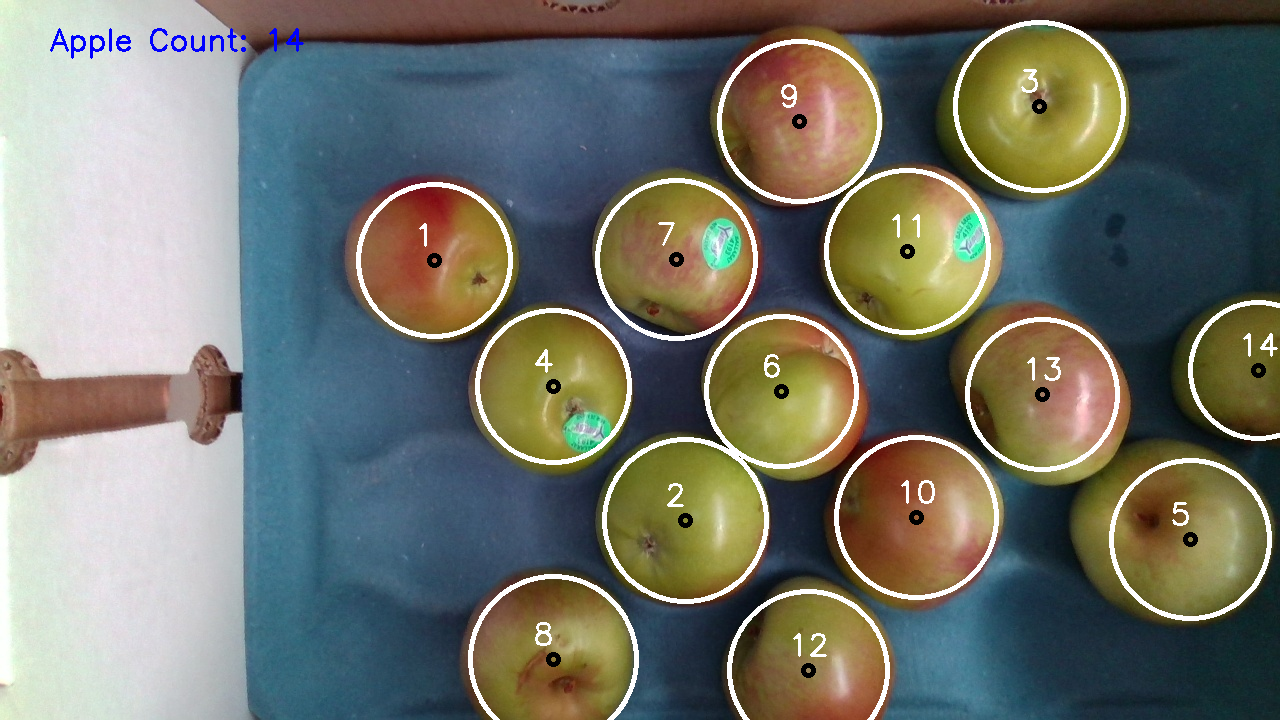

This project was my introduction to machine vision. Using OpenCV the task was to detect apples in an apple box. This was a very fun project that really opened my eyes to the possibilities of machine vision. My final system could definitely use some further refinements and improvements, achieving an accuracy of 99.08% on whole apples but dropping to 82.85% when accounting for partially visible apples. I am excited to explore more in the field of machine vision in the future.

In this project, we were grouped to act as an innovation team within a fictional company, tasked with planning the launch of a new coil winding system. Our responsibilities included design, testing, and conducting market and financial analysis for the proposed solution, complete with production plans.

I led the design and development of the automated cutting process, using widely available and easily replaceable wire cutters within a custom-designed housing to cut the wire and guide the loose end into the next bobbin.

The final prototype worked reliably, successfully winding wire bobbins of various sizes.